Fully Automatic Chocolate Depositing Production Making Line Chocolate Processing Line Equipment Machinery, Chocolate Pouring Machine Equipment Industrial Chocolate Processing Line Single Depositing Head Chocolate Machine

1.Brief Introduction:

1.1 Single Head Chocolate Depositing Machine can be used for the production of single color, two colors (left and right) and pastes central filling chocolates. It has fully automatic functions of moulds pre-heating, depositing, moulds vibrating, cooling, de-moulding and conveying, and adopts PLC control system.

1.2 Chocolate Bar Production Line, confirms to the food GMP standard, is an advanced equipment for producing various shapes chocolate.

1.3 High-degree automation ensures of stale production and saves time, labor force and occupation to serve purpose of reducing the cost.

1.4 Technical Features:

1.4.1 Depositing Type: Pneumatic (AIRTAC)/ Servo Motor (DELTA)

1.4.2 Production Capacity(SPEED): 6-15 Pieces of moulds/minute

1.4.3 Number of Moulds: 280Pieces

1.4.4 Moulds Size: 510*200*30MM

1.4.5 Machine Length:14.7M

1.4.6 cooling tunnel layers : 10 ,termperature 5-10C

1.4.7 output products conveyor length : 2m

1.4.8 PU belt width :490mm

1.4.9 Contactor :Siemens

1.4.10 One material hopper (2 sides for 2 different chocolate pastes) with 1 water temperature control system

1.4.11 Material: Stainless steel machine frame, material hopper, depositing head, vibrating table and machine cover

1.4.12 Voltage: 380V, 50Hz, 3 phases (able to customize)

1.4.13 Motor/Reducer: Dongba, breaker : Hengfu

1.4.14 Pneumatic Air Cylinder: AirTAC (5 pieces)

1.4.15 Temperature Controller mould: Delta

1.4.16 PLC and PLC control panel:Delta

1.4.17 Sensor: Autonics

1.4.18 Transducer (Inverter): Delta

1.4.19 Contactor: Siemens

1.4.20 Cooling System(refrigerator): Copeland 20Hp

1.4.21 Capacity (Ton/Shift):0.4~1.5 , 0.4~1, 0.6~2.5

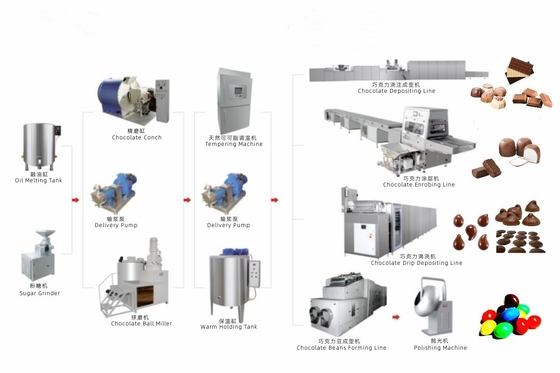

2.Chocolate Processing Flow Chart:

3.Chocolate Depositing Production Line:

4.Technical Parameters of Chocolate Depsoiting Production Lines:

| Model |

PD150

(One Head)

|

PD150

(Two Heads)

|

PD510

( One Head)

|

PD510

(Two Heads)

|

|

Output

(Molds Pcs/Min)

|

6-15 |

6-15 |

6-15 |

6-15 |

| Molds Number (Pcs) |

280 |

330 |

280 |

300 |

| Molds Size(MM) |

330*200*30 |

330*200*30 |

510*200*30 |

510*200*30 |

| Dimension(M) |

16*1*1.6 |

16*1*1.6 |

16*2*1.6 |

16*2*1.6 |

| Total Power(KW) |

19 |

23 |

21 |

25 |

| Total Weight(KG) |

3500 |

4500 |

4000 |

5000 |

5.Main Components Of Chocolate Processing Line:

6.Relative Machines Functions:

6.1 Fat Melting Tank: To melt the cocoa butter and delivering the liquid into chocolate conche machine and refiner when equipped with chocolate feeding pump and flow meter. It features electric heating and automatic temperature control.

6.2 Sugar Grinding Machine: To grind the granulated sugar tin to powder and improve the efficiency of fine grinding without dust.

6.3 Chocolate Conche Machine: To conche and refine chocolate paste and suitable for refining jam, peanut butter or other liquid and pastes.

6.4 Delivery Pump 1: To pump and convey the chocolate paste and other paste products.

6.5 Heat Holding Pump: It is special storage device for refined or ball ground chocolate pastes with electric heating and automatic temperature control. It enables the chocolate paste kept at a rated temperature. Through heat preservation and stirring, it will lower down the moisture content of the chocolate and improve its liquidity to have a longer shelf life and better taste.

6.6 Delivery Pump 2: To pump and convey the chocolate paste and other paste products.

6.7 Tempering Machine: It is essential machine to produce natural cocoa butter chocolate. This device sets a special procedure as per the forming rule of the chocolate paste crystals at different temperatures to strictly and automatically control the required chocolate paste temperature at each en-robing process. This step ensures the quality of the chocolate with stronger fragrance and better taste.

6.8 Chocolate enrobing Machine With Cooling Tunnel:This is a special machine for producing all kinds of different kinds of chocolate pasted coated products. It can enrobe chocolate-paste on the surface of many kinds of foods, such as wafer, biscuits, egg roll, cookie-pie, and etc. This machine can make out the chocolate coated products of special taste and flavor.

6.9 Packing Machine: To pack the finished chocolates into different styles for storage or marketing sales.

7.Main Chocolate Machines Fabrication Photos:

Sugar Grinding Machine:

Chocolate Conch

Chocolate Tempering Machine

Chocolate Depositor

Chocolate Cooling Tunnel

Chocolate Beans Forming and Cooling Unit

Chocolate Packing Machine

8.Chocolate and Moulds Samples:

9.Contact Information:

Mr.Paul Wang MOB/Wechat/Whatsapp:+8613795369808 +85257637597 Email: paul@pandamachinerysh.com

Ms.Isabel Lee Whatsapp:+85246596619 Mob/Wechat ID: +8613127731236 Email: isabel@pandamachinerysh.com

Websites:www.biscuitprocessingline.com www.pandamachinerycn.com www.pandamachinerysh.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!